Stamping and sheet metal processing are essential techniques in modern manufacturing. BulkTEK's innovative approaches to these processes offer significant advantages, ensuring high-quality results and efficient production. This blog delves into the benefits, techniques, applications, and future innovations in BulkTEK's stamping and sheet metal processing.

BulkTEK’s stamping and sheet metal processing provide numerous benefits, including high precision, cost-effectiveness, and versatility. These processes are ideal for producing complex shapes and intricate designs, ensuring that each component meets exact specifications.

BulkTEK employs advanced techniques, such as progressive die stamping, deep drawing, and laser cutting, to achieve superior results. These methods enable the production of high-quality components with minimal waste and reduced lead times, enhancing overall efficiency.

Stamping and sheet metal processing are widely used in various industries, including automotive, aerospace, electronics, and consumer goods. BulkTEK's technology is particularly beneficial for producing components such as brackets, enclosures, and structural parts, where precision and durability are essential.

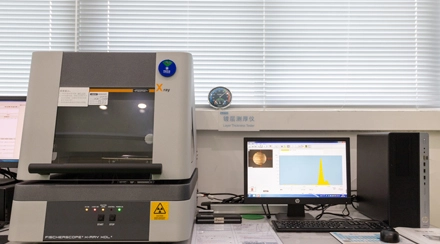

BulkTEK ensures the highest standards of quality through rigorous inspection and testing procedures. Advanced quality control measures, such as optical inspection and material testing, are employed to verify the integrity and accuracy of each component, ensuring consistent and reliable results.

The future of stamping and sheet metal processing is bright, with advancements in automation, digitalization, and material science. BulkTEK is committed to staying at the forefront of these innovations, continuously exploring new technologies and techniques to deliver cutting-edge solutions to its customers.