In the competitive world of industrial manufacturing, precision and efficiency are paramount. BulkTEK's advanced turning machining technology offers unparalleled accuracy and reliability, making it a top choice for various industries. This blog explores the benefits, key features, applications, and future trends of BulkTEK turning machining.

BulkTEK turning machining provides numerous advantages, including high precision, reduced production time, and cost-effectiveness. The technology ensures consistent quality, minimizing errors and waste. This leads to improved product quality and increased customer satisfaction.

BulkTEK's turning machining technology boasts several advanced features, such as high-speed spindles, multi-axis capabilities, and automated tool changers. These features enable complex geometries and tight tolerances, ensuring that even the most demanding specifications are met with ease.

Turning machining is widely used across multiple industries, including automotive, aerospace, medical devices, and electronics. BulkTEK's technology is particularly beneficial for producing intricate components, such as engine parts, medical implants, and electronic housings, where precision is critical.

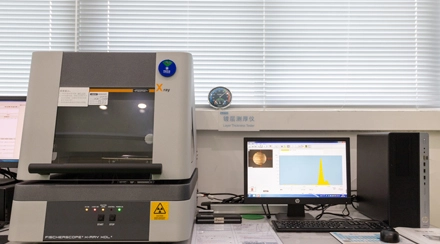

BulkTEK employs rigorous quality control measures to ensure the highest standards of precision and reliability. Advanced inspection techniques, such as coordinate measuring machines (CMM) and in-process monitoring, are used to verify the accuracy of each component, ensuring that every product meets stringent quality requirements.

The future of turning machining technology is promising, with advancements in automation, artificial intelligence, and additive manufacturing. BulkTEK is at the forefront of these innovations, continuously investing in research and development to stay ahead of industry trends and deliver cutting-edge solutions to its customers.