In today's era that pursues extreme quality and efficiency, high-precision machining components have undoubtedly become the precise cornerstone that drives industrial manufacturing to a higher level. As one of the core competencies of the manufacturing industry, high-precision machining components bear the responsibility of improving components quality and ensuring the excellent quality of the final products, as well as precisely meeting the complex and varied market demands. Their wide application and continuous innovation are leading the entire industrial manufacturing industry towards a more refined and intelligent direction.

High precision machining components, as the precision weapons of the manufacturing industry, derive their core value from their excellent forming ability and unmatched dimensional accuracy. These components are often complex in structure and sophisticated in design, capable of achieving precise control at the micron and even nanometer levels, ensuring that every production process meets nearly perfect standards. Though small in size, they embody significant technical challenges and cost investments, truly being the "micro giants" in the manufacturing industry.

In the automotive industry, high-precision machining components are key to improving vehicle performance and ensuring driving safety. Engine components, transmission system elements, etc., all require high-precision manufacturing to ensure efficient and stable power transmission. Meanwhile, safety components such as braking systems also rely on high-precision machining to achieve responsive and reliable braking.

The medical field similarly depends on the support of high-precision machining components. The sharpness and accuracy of surgical instruments rely on high-precision machining technology; the stable operation and accurate measurement of medical devices are also inseparable from these precision components. They provide doctors with reliable diagnostic and therapeutic tools, aiding the realization of precision medicine.

In the aerospace field, high-precision machining components are crucial for the stable operation of aircraft and the exploration of the universe. Whether it is the engine or wings of an airplane, or the propulsion system and navigation equipment of rockets, these components need to withstand extreme environments and complex mechanical requirements. High-precision machining technology provides reliable assurance for the manufacturing of these components.

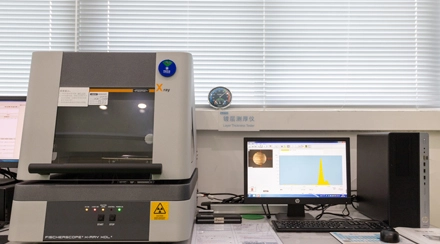

Facing increasingly fierce market competition and continuously escalating market demands, the technological innovation of high-precision machining components has become an important driver of industry upgrading. By introducing advanced machining equipment, optimizing production processes, and improving material performance, precision machining services suppliers continually break through technological bottlenecks, achieving higher levels of machining accuracy and production efficiency. At the same time, with the integrated application of cutting-edge technologies such as intelligent manufacturing, big data, and artificial intelligence, the production process of high-precision machining components is becoming more intelligent and automated, injecting strong momentum into the transformation and upgrading of industrial manufacturing.

High-precision machining components are not only the foundation and support of industrial manufacturing but also an important force driving industry innovation and upgrading. While improving the quality of components, ensuring the quality of final products, and meeting complex and varied market demands, high-precision machining components will enhance the overall competitiveness of the entire industrial manufacturing industry.