Forging is a critical process in manufacturing, enabling the production of high-strength components with excellent mechanical properties. BulkTEK's advanced forging technology offers superior precision and reliability, making it a preferred choice for various industries. This blog explores the benefits, techniques, applications, and future trends of BulkTEK forgings.

BulkTEK’s forging technology provides numerous advantages, including high strength, excellent mechanical properties, and cost-effectiveness. The company’s expertise in forging ensures that each component meets stringent quality standards, delivering reliable and durable results.

BulkTEK employs a range of advanced forging techniques, such as open-die forging, closed-die forging, and precision forging, to achieve superior results. These methods enable the production of complex shapes and intricate designs, ensuring that each component meets exact specifications.

BulkTEK’s advanced processing technology is widely used in various industries, including automotive, aerospace, oil and gas, and industrial machinery. The technology is particularly beneficial for producing components such as crankshafts, gears, and structural parts, where strength and durability are critical.

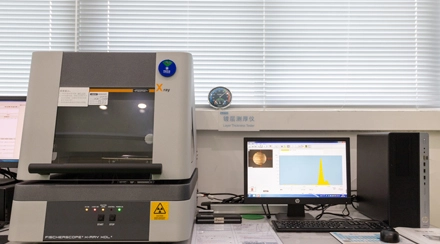

BulkTEK ensures the highest standards of quality through rigorous inspection and testing procedures. Advanced quality control measures, such as ultrasonic testing and material analysis, are employed to verify the integrity and accuracy of each forging, ensuring consistent and reliable results.

The future of forging technology is bright, with advancements in automation, digitalization, and material science. As a leading forgings company, BulkTEK is committed to staying at the forefront of these innovations, continuously exploring new technologies and techniques to deliver cutting-edge solutions to its customers.