High-speed stamping presses, including Bruderer BSTA 60 and Komatsu H1F 110, with progressive die capabilities.

Metals (steel, aluminum, copper), and some plastics.

Max sheet size: 1000mm x 2000mm. Tolerances: ±0.02mm.

Quality Management System: ISO 9001:2015 certified, emphasizing high-volume consistency.

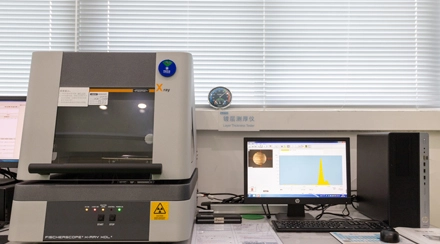

Inspection Equipment: Digital micrometers, hardness testers, and CMM.

Quality Assurance Process: Material certification, in-process inspections, and final part verification using CMM and hardness testers to ensure compliance with specifications.

Stamping applications have revolutionized modern manufacturing by enabling the mass production of high-precision metal components with remarkable efficiency. This versatile process involves pressing or stamping metal sheets into desired shapes using specialized dies and machinery. From automotive parts and electronic components to household appliances and industrial machinery, stamping applications are integral to a wide range of industries. By leveraging advanced stamping techniques, manufacturers can achieve consistent quality, reduce production costs, and accelerate time-to-market. Explore the latest innovations in stamping applications and discover how they are driving the future of manufacturing.