Automated sand casting lines, including DISA MATCH 130 and Hunter HMP-20.

Metals (iron, aluminum, bronze).

Max casting size: 1000mm x 1000mm x 500mm. Tolerances: ±0.5mm.

Quality Management System: ISO 9001:2015 certified, ensuring consistent casting quality.

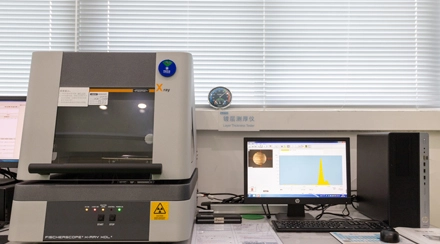

Inspection Equipment: Spectrometers, CMM, and hardness testers.

Quality Assurance Process: Material verification, mold inspection, and final casting inspection using spectrometers and CMM to ensure material composition and dimensional accuracy.

Pattern Creation:

A pattern, typically made of wood, metal, or plastic, is created to form the shape of the final part.

Mold Making:

The pattern is placed in a sand-filled mold box, and sand is packed around it to create the mold cavity.

Core Making:

Cores are used to create internal cavities or complex geometries within the cast part.

Melting and Pouring:

Metal is melted in a furnace and then poured into the mold cavity.

Cooling and Solidification:

The molten metal cools and solidifies within the mold.

Shakeout and Cleaning:

The sand mold is broken away, and the cast part is cleaned and finished.