Die casting machines, such as Bühler Carat 140 and Toshiba DC350.

Metals (aluminum, zinc, magnesium).

Max casting size: 600mm x 600mm x 300mm. Tolerances: ±0.05mm.

Quality Management System: ISO 9001:2015 certified, ensuring precision and quality.

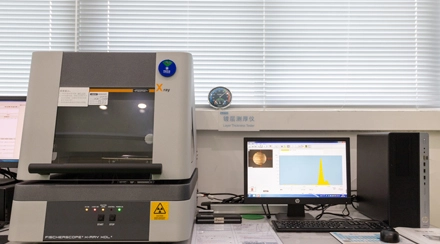

Inspection Equipment: CMM, spectrometers, and hardness testers.

Quality Assurance Process: Material verification, in-process monitoring, and final inspection using CMM and spectrometers to ensure dimensional accuracy and material properties.

Metal mold casting, also known as permanent mold casting, is a manufacturing process where molten metal is poured into a reusable mold made of durable metals like steel or cast iron. The process begins with the design and preparation of the mold, which is often coated with a refractory material to prevent the molten metal from sticking and to extend the mold’s lifespan. The mold is preheated to a specific temperature to ensure proper metal flow and reduce thermal shock.

Once the mold is ready, molten metal is poured into the mold cavity through a gating system, typically using gravity, although low-pressure or vacuum methods can also be employed. The metal cools and solidifies within the mold, forming the desired part. After sufficient cooling, the mold is opened, and the cast part is ejected. Additional finishing processes like trimming, machining, or surface treatment may be required to meet final specifications.

Automotive components: Engine blocks, cylinder heads, transmission parts, and suspension components

Machinery parts: Gears, shafts, bearings, and housings

Industrial components: Valves, pumps, pipes, and fittings

Consumer goods: Kitchenware, tools, and hardware

Art and decorative objects: Sculptures, figurines, and architectural elements

1.Molten Metal Preparation

The desired metal is melted in a furnace or crucible until it reaches the proper temperature.

2. Pouring

The molten metal is poured into the prepared mold.

3. Solidification

The metal cools and solidifies within the mold, taking the shape of the cavity.

4. Mold Removal

Once the metal has solidified, the mold is removed from the casting. This can involve breaking the sand mold in sand casting, or using ejector pins in die casting.

5. Finishing

The casting may require additional finishing processes, such as machining, grinding, or polishing, to achieve the desired surface finish and tolerances.

Metal mould casting methods are widely used in the manufacturing industry to produce high-quality metal parts and components. This process involves creating a mould, typically made of metal, into which molten metal is poured and allowed to solidify. There are several different metal mould casting methods, including die casting, investment casting, and permanent mould casting.

Die casting is a method in which molten metal is forced into a steel mould under high pressure. This process is commonly used to produce complex shapes with high precision and surface finish. Investment casting, also known as lost-wax casting, involves creating a wax pattern that is coated with a ceramic material to form a mould. Once the ceramic material has hardened, the wax is melted and drained, leaving behind a cavity into which molten metal is poured.

Permanent mould casting, on the other hand, uses a reusable mould made of metal to produce multiple castings. This method is suitable for high-volume production of parts with consistent quality and dimensional accuracy. Each of these metal mould casting methods has its own advantages and limitations, and the choice of method depends on factors such as the required part geometry, material properties, and production volume.