Foam pattern making machines and vacuum casting systems, including FOAM-iT! 10 and V-Process 3000.

Metals (aluminum, steel, bronze).

Max casting size: 800mm x 800mm x 400mm. Tolerances: ±0.3mm.

Quality Management System: ISO 9001:2015 certified, ensuring high-quality lost pattern castings.

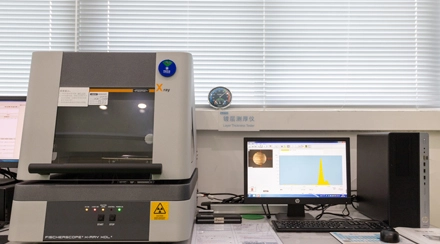

Inspection Equipment: CMM, X-ray inspection, and spectrometers.

Quality Assurance Process: Material verification, mold inspection, and final casting inspection using CMM and X-ray to ensure dimensional accuracy and internal quality.

Lost Plastic Casting: Lost Plastic Casting, also known as Lost Foam Casting, involves creating a foam pattern that is coated with a refractory material. This pattern is then placed in a sand mold. When molten metal is poured into the mold, the foam pattern vaporizes, leaving behind a cavity that the metal fills. This process allows for the creation of complex and precise shapes with smooth surfaces and fine details. It is particularly useful for producing intricate parts with minimal machining required. The main advantage is the ability to produce near-net shape castings with high dimensional accuracy and surface finish.

Sand Casting: Sand Casting, on the other hand, involves creating a mold from a mixture of sand and a binding agent. A pattern, typically made of wood, metal, or plastic, is used to form the cavity in the sand mold. Once the mold is prepared, molten metal is poured into the cavity and allowed to solidify. After cooling, the sand mold is broken away to reveal the cast part. Sand Casting is versatile and cost-effective, suitable for producing large and heavy parts. It is widely used in various industries for casting metals like iron, steel, aluminum, and bronze.

In summary, Lost Plastic Casting is ideal for high-precision, complex parts, while Sand Casting is more versatile and cost-effective for larger, simpler components.