Wax injection machines, ceramic shell building systems, and induction furnaces, such as MPI 25 and Inductotherm VIP Power-Trak.

Metals (stainless steel, aluminum, titanium).

Max casting size: 500mm x 500mm x 500mm. Tolerances: ±0.1mm.

Quality Management System: ISO 9001:2015 certified, ensuring high precision and quality.

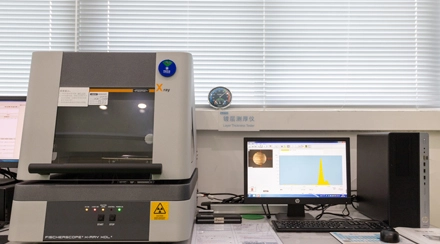

Inspection Equipment: CMM, X-ray inspection, and spectrometers.

Quality Assurance Process: Material verification, in-process inspections, and final inspection using CMM and X-ray to ensure dimensional accuracy and internal integrity.

Intricate Details: Investment casting is capable of producing parts with extremely fine details and complex geometries that would be difficult or impossible to achieve using other methods.

High Accuracy: This process provides exceptional dimensional accuracy and tight tolerances, making it ideal for applications requiring precise fit and function.

Smooth Surface Finish: Investment castings typically have a smooth and consistent surface finish, often eliminating the need for extensive finishing operations.

Wide Range of Materials: Investment casting can be used to produce parts from a variety of metals, including ferrous and non-ferrous alloys.

Cost-Effective for Complex Parts: While investment casting can be more expensive than some other methods for simple parts, it becomes more cost-effective for complex shapes with intricate details.

Aerospace: Turbine blades, Engine components, Aircraft parts

Automotive: Engine components, Transmission parts, Suspension components, Brake systems

Medical Devices: Surgical instruments, Dental implants, Prosthetic components

Jewelry: Fine jewelry pieces, Custom jewelry designs

Industrial Components: Valves Pumps, Gears Precision tools

Pattern Creation: A pattern is made from wax or another meltable material. This pattern is coated with a refractory material to form the mold shell.

Coating: The pattern is dipped in a refractory slurry and then sprinkled with fine sand, creating a sturdy outer shell. This process may be repeated multiple times to achieve the desired thickness and strength of the shell.

Wax Removal: The coated mold is heated to melt and remove the internal wax pattern, leaving a hollow cavity.

Pouring: Molten metal is poured into the cavity, filling the mold shape. The metal cools and solidifies, forming the desired part.

Shell Removal: The refractory shell is broken or removed to extract the cast metal part.

Post-Processing: The castings undergo machining, cleaning, and surface finishing to achieve the required dimensions and surface quality.

High precision investment casting, also known as lost wax casting, is a manufacturing process used to create intricate and complex metal parts with high levels of accuracy and detail. The process begins with the creation of a wax pattern, which is then coated with a ceramic shell to form a mold. The wax is then melted out of the mold, leaving behind a cavity in the shape of the desired part. Molten metal is then poured into the cavity, filling the space and taking on the shape of the mold. Once the metal has solidified, the ceramic shell is broken away, revealing the final metal part. This method allows for the production of parts with very tight tolerances and fine surface finishes, making it ideal for applications in industries such as aerospace, automotive, and medical.