High-precision CNC grinding machines with capabilities for surface, cylindrical, and centerless grinding. Machines include Okuma GA-26T and Studer S33.

Metals (steel, aluminum, titanium), ceramics, and composites.

Max workpiece size: 600mm diameter, 2000mm length. Tolerances: ±0.001mm.

Quality Management System: ISO 9001:2015 certified, ensuring consistent quality and continuous improvement.

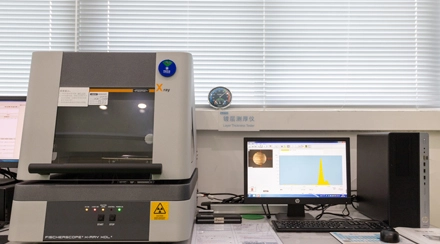

Inspection Equipment: Coordinate Measuring Machine (CMM), surface roughness testers, and micrometers.

Quality Assurance Process: Incoming material inspection, in-process monitoring, and final inspection using CMM and surface testers to ensure precision and adherence to specifications.

Precision grinding machines are essential tools in the manufacturing industry, known for their ability to produce highly accurate and smooth surface finishes. These machines are crucial for achieving the tight tolerances and fine finishes required in various high-precision applications.

High Accuracy:

Capable of achieving extremely tight tolerances, often within microns.

Superior Surface Finish:

Produces exceptionally smooth surfaces, essential for high-performance components.

Versatility:

Suitable for a wide range of materials, including metals, ceramics, and composites.

Advanced Control Systems:

Equipped with CNC (Computer Numerical Control) for precise and repeatable operations.

Robust Construction:

Built to withstand heavy-duty operations and maintain accuracy over time.

Grinding Wheel Selection

The right grinding wheel is chosen based on the material, surface finish, and part geometry, with factors like abrasive type, grit size, and bond material being key to the selection.

Setting Up the Machine

The grinding wheel is mounted and aligned on specialized machines, with adjustments made to settings like speed, feed rate, and depth of cut to ensure precision.

Grinding Process

Surface Grinding: The wheel moves across the part to achieve a flat, smooth surface.

Cylindrical Grinding: The part rotates while the wheel grinds its outer surface.

Centerless Grinding: The part is held by a regulating wheel, and the grinding wheel shapes it without using centers.

Cooling and Lubrication

Coolants or lubricants are used to prevent overheating, remove debris, and maintain efficiency during the grinding process.

Finishing and Measuring

After grinding, the part may be polished, and precision instruments are used to measure its dimensions and ensure it meets required tolerances.

Inspection and Quality Control

Parts are inspected for defects, and the grinding process is adjusted as needed to maintain dimensional accuracy and quality throughout production.