Hydraulic compression molding presses, including Wabash MPI Genesis and French Oil PH Series.

Plastics, rubber, and composites.

Max mold size: 1000mm x 1000mm. Tolerances: ±0.1mm.

Quality Management System: ISO 9001:2015 certified, ensuring high-quality molded parts.

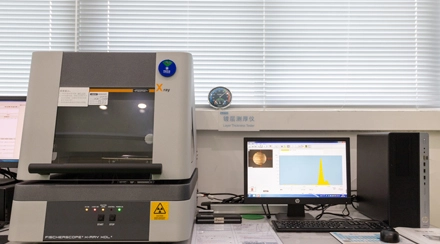

Inspection Equipment: CMM, digital calipers, and tensile testers.

Quality Assurance Process: Material verification, mold inspection, and final part inspection using CMM and tensile testers to ensure dimensional accuracy and material strength.