Cold heading machines and thread rolling machines, such as National Machinery FORMAX 2000 and Reed Machinery R-200.

Metals (steel, aluminum, brass).

Max workpiece diameter: 50mm. Tolerances: ±0.02mm.

Quality Management System: ISO 9001:2015 certified, ensuring precision and quality.

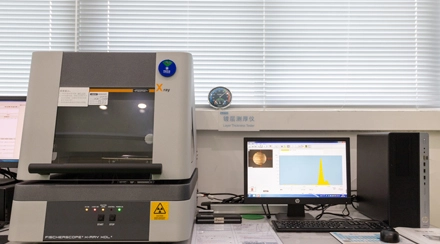

Inspection Equipment: CMM, digital calipers, and hardness testers.

Quality Assurance Process: Material verification, in-process inspections, and final inspection using CMM and hardness testers to ensure dimensional accuracy and material properties.

Improved Material Properties: Cold forming can enhance the material's strength, hardness, and fatigue resistance. This is due to the process of work hardening, where the metal's internal structure is realigned.

Enhanced Dimensional Accuracy: Cold forming provides exceptional precision and tight tolerances, ensuring parts meet strict quality standards.

Reduced Waste: As there's minimal material removal, cold forming results in less waste compared to processes like machining.

Improved Surface Finish: Cold forming can produce parts with a superior surface finish, often eliminating the need for additional finishing processes.

Low-carbon steel: Widely used due to its good formability, strength, and cost-effectiveness.

Stainless steel: Offers excellent corrosion resistance, making it ideal for applications exposed to harsh environments.

Aluminum alloys: Lightweight and corrosion-resistant, making them suitable for applications where weight reduction is critical.

Copper alloys: Possess good electrical and thermal conductivity, often used in electrical and heat transfer components.

Brass: Known for its machinability, ductility, and corrosion resistance.

Titanium alloys: High-strength, low-weight, and corrosion-resistant metals used in aerospace and medical applications.

1. Material Selection

The first step in precision cold forming is selecting suitable materials, typically ductile metals such as steel, aluminum, or brass, which can effectively withstand deformation at room temperature.

2. Blank Preparation

Next, the metal is cut into blanks or pre-forms that are slightly larger than the final dimensions of the part to allow for adequate material flow during the forming process.

3. Tool Design

Following that, specialized dies and tooling are designed specifically to shape the material, ensuring that the tooling is engineered for high precision and repeatability.

4. Cold Forming Process

The cold forming process begins when the prepared blank is fed into the forming machine, where mechanical forces are applied through the dies to deform the material into the desired shape.

5. Finishing Operations

After the initial forming, the parts may undergo additional finishing operations, such as trimming, machining, or surface treatments, to achieve the required tolerances and surface finishes.

6. Quality Control

Once the parts are finished, they undergo quality control inspections to verify dimensional accuracy, surface finish, and mechanical properties using various measurement techniques.

7. Packaging and Delivery

Finally, after passing quality checks, the parts are carefully packaged for shipment to customers or for further assembly into larger products.

1. Automotive Industry

Cold forming parts are utilized to manufacture components such as gears, shafts, and fasteners, which require high strength and precision for performance and safety.

2. Aerospace Industry

In aerospace, cold-formed parts like brackets, fittings, and structural components are critical for reducing weight while maintaining strength and reliability.

3. Electronics

Cold forming parts are employed to create intricate parts for electronic devices, including connectors, housings, and heat sinks, where precision and compactness are essential.

4. Medical Devices

The medical industry uses cold-formed components such as surgical instruments, implants, and housings for medical devices, which must meet stringent quality and precision standards.

5. Construction

Cold forming is used to produce structural elements like beams, brackets, and connectors that contribute to the integrity of buildings and infrastructure.

1. Improved Strength

Cold forming compresses the metal's grain structure, increasing tensile strength and hardness without the need for heat treatment. The result is a stronger, more durable part that performs well under stress.

2. High Dimensional Accuracy

Cold forming produces tight tolerances and consistent dimensions, reducing the need for secondary machining. This leads to better quality control and faster assembly.

3. Excellent Surface Finish

Since the process doesn't involve cutting, the surfaces remain smooth and free from burrs. A superior finish reduces wear and tear during assembly and improves part aesthetics.

4. Material Efficiency

Cold forming minimizes waste by reshaping metal without removing material. Compared to machining, which generates chips, this process is more cost-effective and sustainable.

5. High Production Speed

Once the tooling is set up, cold forming machines can produce large volumes of parts quickly and consistently, making it ideal for high-volume manufacturing.