The maximum diameter of CNC processed parts is up to 600mm.

The min diameter of precision cnc machining parts is 1.0 mm

The max length of cnc precision parts is up to 1000mm

Up to 3000mm (Diameter < 55mm)

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools such as lathes, mills, routers, and grinders. The process begins with a digital design, typically created using CAD (Computer-Aided Design) software. This design is then converted into a CNC program, often using CAM (Computer-Aided Manufacturing) software, which generates a series of precise instructions (G-code) that guide the machine’s movements.

CNC machining offers high precision, repeatability, and efficiency, making it ideal for producing complex parts with tight tolerances. The process can handle a wide range of materials, including metals, plastics, wood, and composites. It is widely used in various industries, such as aerospace, automotive, medical, and electronics, for both prototyping and full-scale production.

One of the key advantages of CNC machining is its ability to produce consistent and high-quality parts with minimal human intervention, reducing the likelihood of errors and increasing production speed. Additionally, CNC machines can operate continuously, 24/7, further enhancing productivity. The technology also allows for quick adjustments and modifications, making it highly adaptable to changing design requirements and production needs.

BulkTEK processes its products in strict accordance with ISO 9001 standards.

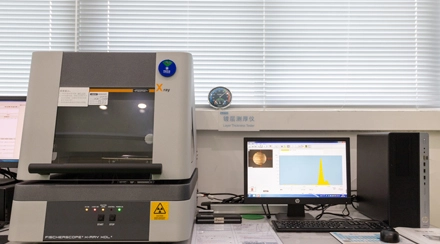

BulkTEK Laboratory has municipal-level standard testing and inspection capabilities.

BulkTEK has complete professional testing and inspection equipment, which can cope with various parts inspection requirements. No external inspection required, reducing delivery time.

BulkTEK regularly submits its testing and inspection equipment to professional calibration institutions for calibration every year to ensure accurate measurement data.

PPAP Level 3 document

EN10204 - 3.1

Initial Samples Report

Pre‐Shipment Inspection Report

Third Party Test Report(RoHS & Reach)

CNC Milling: CNC milling involves the use of rotating cutting tools to remove material from a workpiece, allowing for the creation of complex shapes and features.

CNC Turning: CNC turning rotates the workpiece while a stationary cutting tool removes material, making it ideal for producing cylindrical parts.

CNC Drilling: CNC drilling precisely creates holes in a workpiece using a rotating drill bit, ensuring accurate depth, diameter, and location.

CNC Grinding: CNC grinding employs an abrasive wheel to remove material and achieve high surface finishes and precise dimensions.

CNC Routing: CNC routing is used for cutting and shaping softer materials like wood and plastics, similar to milling but tailored for different substrates.

CNC Electrical Discharge Machining (EDM): CNC EDM uses electrical discharges to erode material, perfect for machining hard materials and intricate shapes.

High Precision and Accuracy: BulkTEK utilizes advanced CNC technology to produce parts with exceptional precision, ensuring they meet strict tolerances and specifications.

Rapid Prototyping: The company can quickly produce prototypes, allowing for faster iterations and improvements during the design phase.

Versatile Material Options: BulkTEK offers machining services for a wide range of materials, including metals, plastics, and composites, catering to diverse project requirements.

Custom Solutions: They provide tailored machining services to meet specific client needs, ensuring that every part is designed and produced according to individual specifications.

Short Lead Times: The efficient workflow and modern machinery enable BulkTEK to offer shorter lead times, helping clients meet tight deadlines.

CNC Machining: CNC (Computer Numerical Control) machining involves removing material from a solid block (usually metal, plastic, or wood) using cutting tools like mills, lathes, or drills. The material is gradually shaped to the desired specifications via precise, computer-controlled movements. Offers very high precision and smooth surface finishes. CNC machines can achieve tolerances as tight as 0.001 mm, making them ideal for producing parts that require exact dimensions and a high-quality finish.

3D Printing: 3D printing, or additive manufacturing, builds objects layer by layer based on a digital model. It adds material (usually plastic, resin, metal powder, or even concrete) in precise layers to create the final part, unlike CNC, which removes material. While some 3D printing technologies (like SLA or SLS) can produce detailed parts, the surface finish typically isn’t as smooth as CNC-machined parts. Additionally, precision in 3D printing can be lower, especially with more affordable FDM (Fused Deposition Modeling) printers.