CNC automatic lathes such as Citizen Cincom L32 and Star SR-20RIV, equipped with bar feeders and live tooling.

Metals (brass, stainless steel, aluminum), plastics, and composites.

Max workpiece diameter: 32mm. Tolerances: ±0.005mm.

Quality Management System: ISO 9001:2015 certified, focusing on precision and reliability.

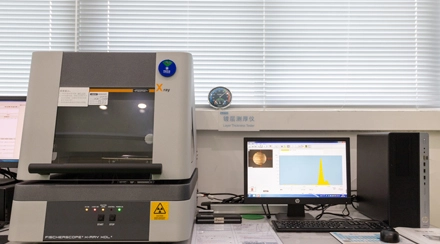

Inspection Equipment: Optical comparators, CMM, and digital calipers.

Quality Assurance Process: Rigorous incoming material checks, real-time process monitoring, and final inspection using CMM and optical comparators to ensure dimensional accuracy.

Discover the unparalleled efficiency and precision of our state-of-the-art automatic lathe machining. Designed for high-volume production, this machine ensures consistent quality and reduces cycle times, making it the perfect addition to any modern manufacturing facility. Whether you’re producing intricate components or high-precision parts, our automatic lathe delivers exceptional performance and reliability. Explore the features and benefits that set our automatic lathe apart and see how it can transform your production process.

High Production Efficiency: Automatic lathe machining can operate continuously, reducing the need for manual intervention and increasing production speed.

Versatility: Automatic lathe machining can process a variety of materials and complex shapes, adapting to different production needs.

Increased Safety: Automatic lathe machining reduces the risk of worker exposure to hazardous equipment, enhancing workplace safety.

Programmability: Many automatic lathes can be programmed for quick setup and adjustment, making it easy to switch between different production tasks.

Long Operating Hours: Automatic lathe machining can run during the night or in unattended conditions, improving production continuity.