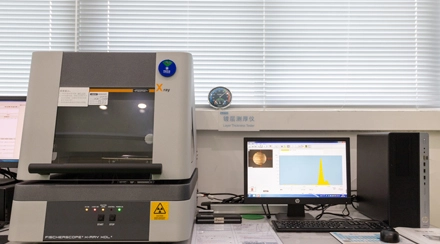

When it comes to special parts, BulkTEK has a set of rigorous quality control inspection systems and solutions from raw materials to the finished product. First of all, when we purchase raw materials, we will test its composition, mechanical properties. Secondly, the first inspection, process inspection, and final inspection method will be applied to ensure the quality during the production. After the production, we will inspect the product appearance, size, functionality, coating, anti-corrosion ability and packaging based on customers requirements. As a leading supplier of special parts, BulkTEK is equipped with advanced laboratories and wide-range of equipment to ensure the quality.

As a professional special parts supplier, BulkTEK has a thorough quality control system and has ISO 9001 & ISO 14001 certifications. We ensure that every step of the process, from raw materials to finished components, is well monitored to guarantee the stability and precision of products. Meanwhile, we have a advanced laboratory to conduct rigorous inspection for each product, and judge whether it satisfy the requirements from our customers.

BulkTEK has been engaged in serving special parts for 25 years, and we have gained valuable experience. We can provide assistance to customers since the design stage. We are proud that we have served more than 200 customers in Europe and the United States, and also established a stable cooperation with a number of renowned companies, including WURTH, REYHER, BUFAB, FASTENAL, MOTION INDUSTRIES, etc.

BulkTEK supplied over 10,000 special parts to customers worldwide for over 25 years. We have accumulated a large number and a wide range of special parts, and we are capable of handling a wide variety of customization requirements. Nowadays, we can supply over 120 types of raw materials, over 20 types of surface treatments, and up to a dozen different types of heat treatments.

1. Cutting-Edge Manufacturing Techniques

BulkTEK continuously invests in the latest manufacturing technologies to enhance precision and efficiency.

2. Material Science Innovations

We leverage breakthroughs in material science to offer a wide range of materials, including high-strength alloys, composites, and specialized polymers. These innovations allow us to produce parts that are not only durable but also optimized for specific applications across various industries.

3. Sustainable Manufacturing Practices

BulkTEK is committed to sustainability. We have implemented eco-friendly practices such as waste reduction, energy-efficient machinery, and the use of recyclable materials. These efforts help minimize our environmental footprint while maintaining high production standards.

4. Custom Solutions and Flexibility

BulkTEK prides itself on its ability to provide custom solutions tailored to the unique needs of each client.